Overall approach

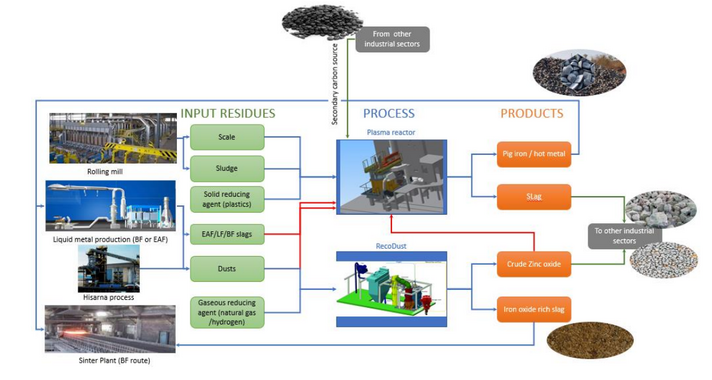

ReMFra is a research project within the frame of the Clean Steel Partnership (Horizon Europe) to develop and validate a highly efficient industrial scale pyrometallurgical smelting and reduction plant for the recovery of metals and minerals contained in a variety of steelmaking residues. The treatment route is based on 2 processes (see Figure 1), a plasma reactor for the treatment of coarse-grained residues such as scale, sludge, and secondary metallurgical slag, and the RecoDust process for fine-grained residues.

The activities of K1-MET within the RemFra project focus on smelting campaigns with the RecoDust pilot plant at the Chair of Thermal Processing Technology (project partner University of Leoben) with different feedstocks (dusts from the BOF, EAF and the Hisarna smelting reduction process), on DEC activities (dissemination, exploitation, and communication) as well as on Key Performance Indicator (KPI) monitoring.

Objectives

The overall goals of this 42-month project are:

- Development and implementation of highly efficient technologies for recovering metals and mineral fraction from steelmaking residues

- Full by-product testing and evaluation

- Use of smart sensor and dedicated Big Data analytics to develop and optimize decision-supported systems

- Evaluation of the slag utilization originating from the plasma process

- Integration of energy recovery solutions from the pyrometallurgical residue treatment

- Reduction of CO2 emissions

Framework

Project timeline:

2022-12-01 to 2026-05-31

Funding scheme:

Call: Horizon Europe Clean Steel Partnership (HORIZON-CL4-2021-TWIN-TRANSITION-01-19)

Type of action: Innovation Action (IA)

Granting authority: European Health and Digital Executive Agency

The ReMFra project receives funding by the European Union (Grant Agreement no. 101058362).

Project consortium:

Starting with the project coordination, the consortium is composed as follows:

- Tenaris Dalmine SPA (Italy, Coordination)

- Barna Steel SA (Celsa Group) (Spain)

- European Steel Technology Platform (Belgium)

- FEhS Institut fuer Baustoffforschung e.V. (Germany)

- K1-MET

- Montanuniversitaet Leoben, Chair of Thermal Processing Technology (Austria)

- RINA Consulting – Centro Sviluppo Materiali (Italy)

- Tata Steel Netherland Technology BV (The Netherlands)

- Tenova SPA (Italy)

- thyssenkrupp Steel Europe (Germany)

- voestalpine Stahl GmbH (Austria)

DE

DE EN

EN