Overview

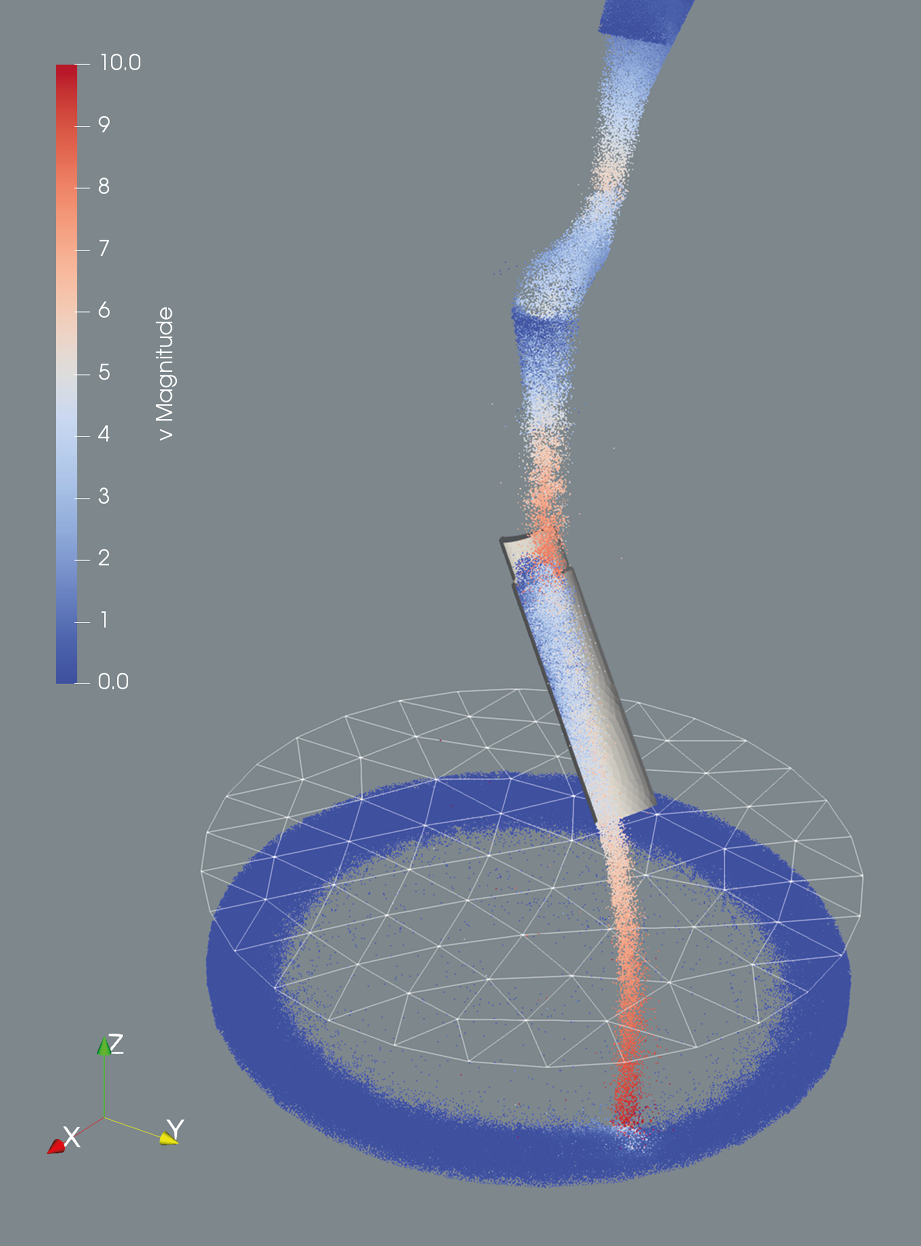

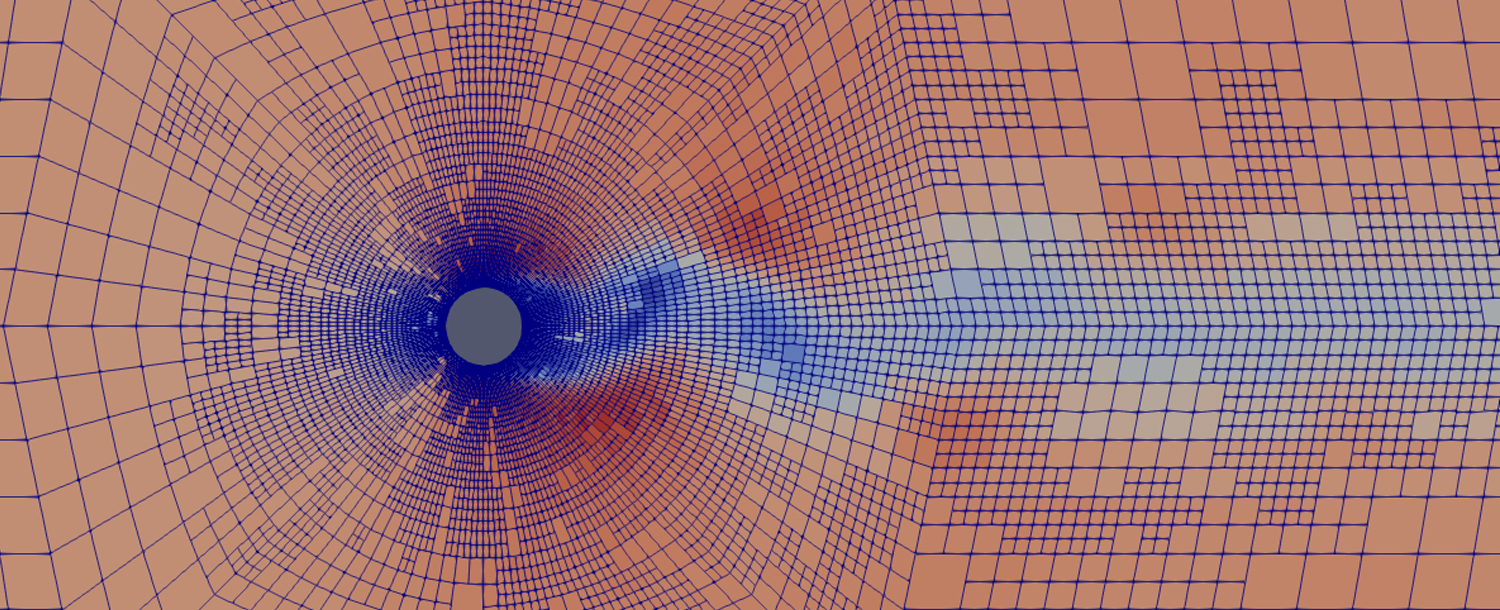

Area 3 is focused on the application of modelling approaches to new and existing metallurgical processes. Data analysis is carried out to increase the process efficiency of steelmaking. Modelling helps to understand and predict the behaviour of complex systems or processes. It allows researchers to study and analyze different scenarios, make predictions, and test hypotheses without the need for costly or time-consuming real-world experiments. Models or prototypes can range from simple mathematical calculations to challenging computer simulations. Area 3 uses both open source and commercial tools and software frameworks for detailed simulations in Computational Fluid Dynamics (CFD), Discrete Element Method (DEM) or Finite Element Method (FEM) modelling.

Numerical simulations of fluids and particulate flows are a widely used tool in research and development activities on industrial processes. It means using computer models and calculations to understand how liquids and gases behave in different situations. These methods have been applied successfully at K1-MET in the investigation of metallurgical processes along the steelmaking chain. These processes range from the blast furnace (BF) to different liquid metal processes in a steel plant, such as the converter treatment, Ruhrstahl-Heraeus (RH) degassing, ladle furnace treatments, and continuous casting. For a deeper insight and further explanations, please refer to the introduction of Area 1.

Apart from developing process simulations and models, the further development of simulation methodologies and techniques are very important in future activities. Existing simulation models are expanded, and different methods are united and applied to larger projects. Experimental investigations will show how well the models work. Accompanying simulation activities for Area 1 and 2 are planned to support experimental developments there.

The third aspect is digitalization, data analytics and evaluations from a process-oriented point of view. Artificial intelligence tools like machine learning and big data analytics are used to understand large quantities of complex process data. Moreover, solutions to important questions on process understanding and optimal process operation will be obtained.

Planned measures

The overall strategy of Area 3 is to improve knowledge, develop new simulation models and unite existing methods. The cooperation with scientific partners enables to profit from each other’s expertise. With their activities in numerical simulations, K1-MET and its partners contribute to open-source software projects with their own developed specific models or calculation methods. Simulation methodologies and results are not only shared with the involved partners, but also with the community and the public. These are great secondary effects.

Numerical simulation activities will be accompanied by laboratory experiments and model plant measurements. This will offer new insights into physical phenomena. Big data approaches will help to understand processes in real life. Fast simulations will contribute to a higher simulation efficiency, and this will increase the gained knowledge.

Another important orientation is the roadmap to the digital transformation of the steel industry by using artificial intelligence. By doing so, energy and resources will be saved, processes enhanced, and CO2 reduced. In this way, our planet is becoming more sustainable.

DE

DE EN

EN

![[Translate to English:]](/fileadmin/_processed_/b/5/csm_area3_weiss_f1f233eda7.png)