Introduction

This project aims at employing advanced data analyses and methodology, such as machine learning, in order to investigate process data and parameters from different processes in the steelmaking chain, generating process understanding and knowledge on correlations and causations in operation, as well as develop advisory or warning systems for the operator in order to adjust and improve operation. Topics range from questions on operation and stability of the blast furnace (BF) to the production of ultra-clean steels with the Ruhrstahl-Heraeus (RH) plant and the optimization of the casting process.

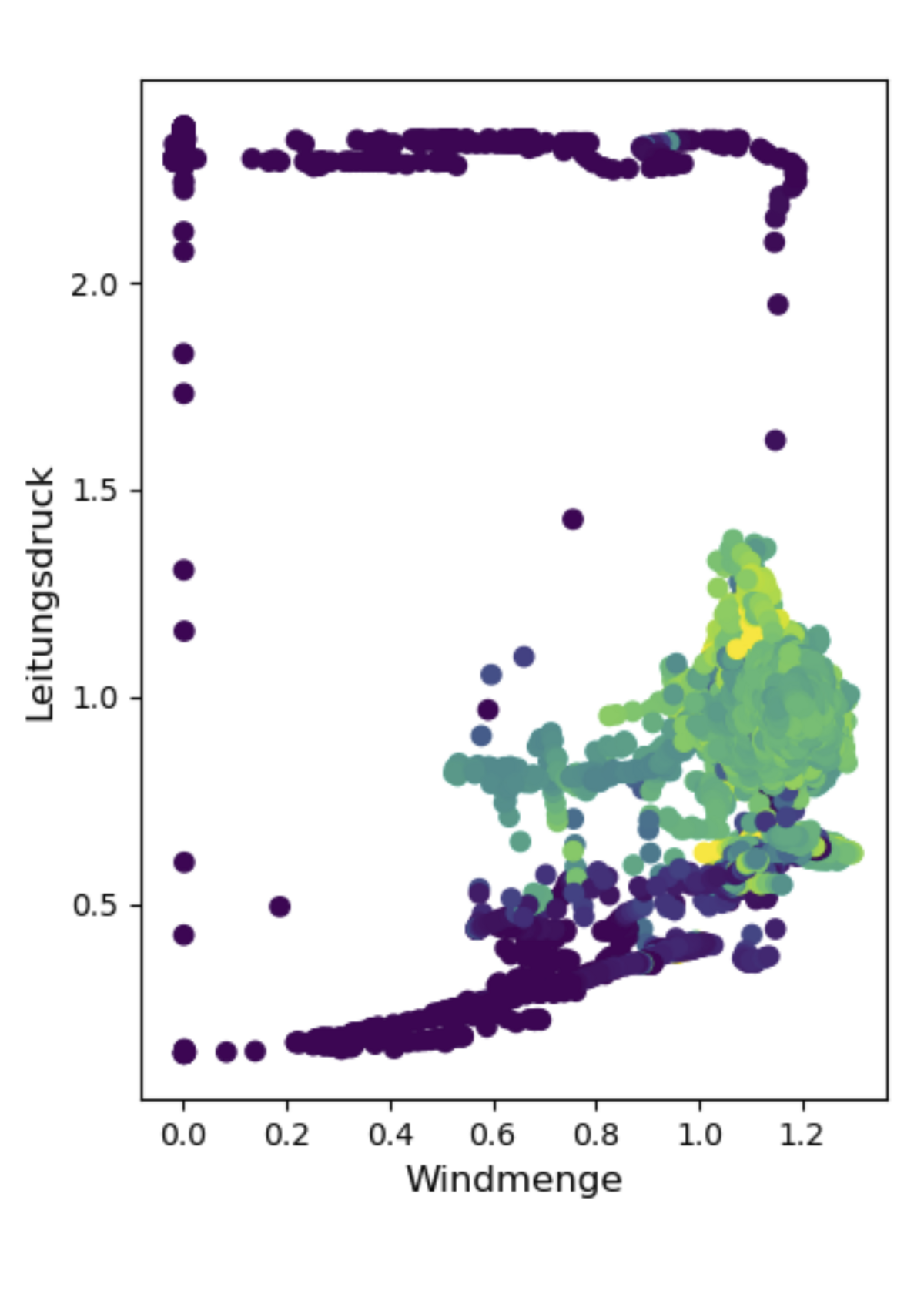

The blast furnace process has been the subject of extensive data science analyses considering the complete plant. Attempts are made to extract a characterization of the overall behavior of the furnace, evaluating a large amount of data from various sources around the process. However, this has proven to be very difficult, since the process as a whole is highly complex, with many different temporal and spatial scales involved as well as complicated dynamics and interplay of many different material and energy flows. This makes a causal connection of overall BF behavior to available measurements a challenge. The approach envisaged here is therefore to focus on specific aspects of the process first, where a concrete problem is posed, and advanced data analytics can be employed in a very target-oriented way, in order to optimize certain target values or key process indicators identified beforehand. From this modular approach, an understanding of larger contexts will then be achieved.

The RH plant is the key vessel to adjust the desired alloy concentrations in the steel. Alternative CO2 free steel production lines result in a larger variety of pig iron compositions. As alternative steel production routes increase in importance for the steel production, the demands on secondary metallurgy increase as well, causing the RH and CC facilities at integrated steel plants to become a bottle neck in the production line. Accordingly, any measure to deepen the understanding of the process steps or to reduce the process time is valuable. One option to achieve these goals is to enhance the monitoring of the RH process, in order to be able to reduce process times and save energy and resources. In the case of continuous casting, defect detection and analysis in the subsequent rolling processes is an important topic that can be traced back to variations in the casting stage. An improved understanding of process parameters and data of the casting stage is thus crucial in order to minimize steel strip defects.

While the different questions and tasks in the work packages of this project are a priori not connected, the methodologies and approaches to analyze and understand data are similar from case to case. For image data, convolutional neural networks (CNNs) are used, whereas for linear time series data, clustering algorithms or recurrent neural networks (RNNs) for pattern recognition can be employed. The unification of all these topics into one project aims to establish a better understanding of data-driven scientific approaches in general, being able to compare different use cases and build up a strong knowledge base and competences with a varied range of applications.

Objectives and Motivation

- Analyses of mass balances in the BF operation and development of a warning and advisory system for improved process and steel quality

- Investigation and prediction of temperature irregularities in the BF bottom and hearth for improved BF operation and lifetime

- Analyses of charging models and profiles and development of an advisorysystem to optimize charging strategies and improve BF process behavior

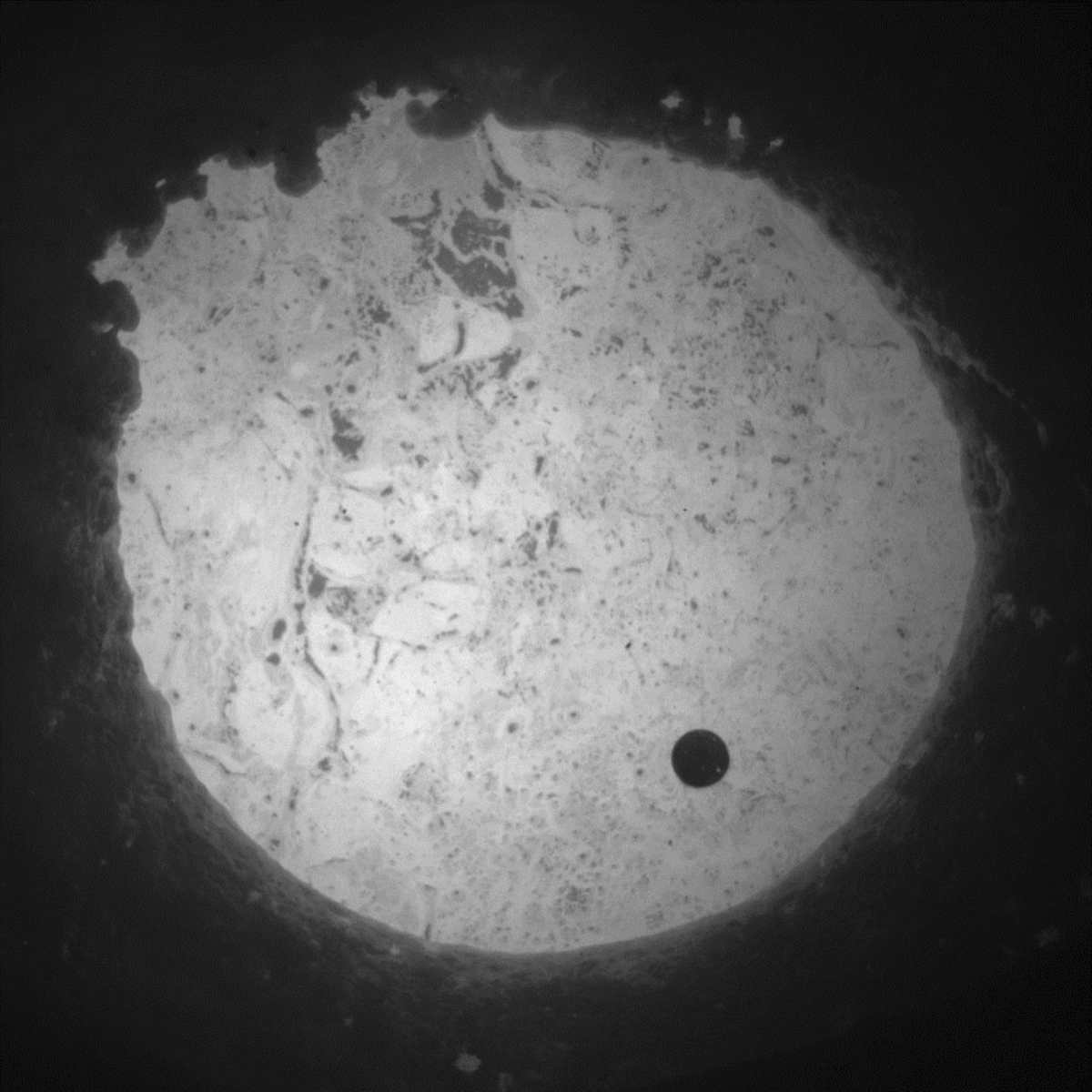

- Analyses of raceway blockages and possible correlations with process parameters and image data for improved process knowledge and predictive maintenance for tuyeres

- Investigation of image and sensor data for state classification at the RH plant and development of an advisory and warning system for early detection of irregular states to prevent serious damage to the plant

- Prediction of slivers on the strip surface based on a hybrid approach and combination of data from sensors in the CC mold with physical/ metallurgy-based mathematical models

Methodology

- Combination of existing theories and metallurgical process knowledge with cause-and-correlation studies of the available data

- Identification and application of appropriate machine learning methods (e.g., clustering algorithms, classification methods, neural networks, regressions) for image and sensor data evaluation

- Consideration of new sensor systems and application of appropriate solutions

- Utilization and combination of radar and camera data as well as top gas temperature measurements with CFD simulations and literature studies to develop optimized charging strategies for the blast furnace

- Combination of image and linear data for the RH and casting applications

- Development of physical-mathematical models, simulations and machine learning approaches for description and prediction of processes as well as validation and improvement of existing models

Results and Application

By the extensive use and combination of classic analytical methods, simulations and machine learning algorithms, a strong knowledge base and competences with a varied range of applications will be built up and process knowledge and understanding will be improved. Advisory and warning systems as well as prediction tools will be developed for improving process control, monitoring and steel quality as well as reducing downtimes and extending the lifetime of the plants.

DE

DE EN

EN![[Translate to English:]](/fileadmin/_processed_/b/5/csm_area3_weiss_f1f233eda7.png)