Project MissingLink

MissingLink – the 4th pillar of material plastics recycling to optimise Austrian recycling quotas

Overall approach

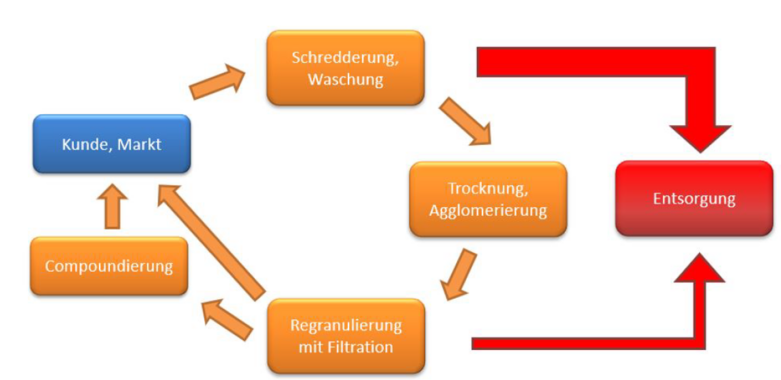

The post-consumer recycling process (washing line, pre-drying, agglomeration, regranulation, see Figure 1), which is so important for a plastics recycling economy, generates a waste stream of approx. 20% of the input, 15% of which still contains a high proportion of plastics. This leaves a fraction enriched with thermoplastics, which is currently only disposed by incineration with massive additional payments. The "MissingLink" project aimed at significantly reducing the residual moisture in a very cost-efficient way to subsequently enabling material recycling.

The "MissingLink" for post-consumer - recyclers can be granulated slag from the blast furnace as recycling filler. Granulated slag has a special property, namely hydraulic activity. The water is incorporated relatively slowly and sustainably into the silicate lattice (latent drying as in concrete hardening), and the moisture thus remains bound in a recyclable form for possible subsequent material recycling. This makes pelletization possible. Dry plastic pellets are the next "MissingLink" and can be easily transported, conveyed, and dosed both, on processing equipment, and in the blast furnace process, and thus recycled.

As a reducing agent and "MissingLink" in the blast furnace process (also equivalent to material recycling), plastic pellets can replace coal dust, saving other naturally mined resources. They also enable "filler recycling" because hydraulically active recycled filler is recovered from them again in the form of blast furnace slag, which is then finely ground up. But this hydraulically active recycled filler is even more of a "missing link" as a substitute for naturally mined mineral fillers in plastics compounding.

In Europe, about 10 million tons of mineral fillers are mined and used in plastics each year, of which potentially more than a quarter could be replaced by such a recycled filler. With over 100 post-consumer recyclers in Europe, "MissingLink" has a huge impact on the recycling rate across Europe, where we are talking about around 500,000 tons of such a waste fraction that could be made available for recycling in the future. Every post-consumer recycler thus becomes a potential supplier of a substitute reducing agent for the blast furnace process and receives a hydraulically active recycled filler in return. In addition, the major compounders in Europe will receive a new recycled filler as a functional substitute for naturally mined mineral fillers.

Objectives

- Recycling of a previously considered waste fraction via latent drying (latent drying should dry the wet post-consumer waste fraction to below 1% residual moisture).

- Pelletization of the dried residual fraction

- Use of the pellets, depending on the plastic matrix, as part of direct material recycling in plastics processing (injection molding, extrusion), in plastics compounding or in the blast furnace as a substitute reducing agent

- Use of granulated blast furnace slag as mineral filler for reinforced plastics

Project timeline:

2022-04-01 to 2024-03-31

Funding scheme:

COIN - Network program line 14th Call

The Project MissingLink receives 46% funding by the Austrian Federal Ministry for Labour and Economy and is coordinated by the Austrian Research Promotion Agency (Grant Agreement number FO999895489).

DE

DE EN

EN