Project DESTINY

Development of an Efficient microwave System for material Transformation in energy INtensive processes for an improved Yield

Keraben, the coordinator of the DESTINY project, describes in the following videos the key figures and data about the DESTINY project and its benefits for energy-intesive industries:

Overall approach

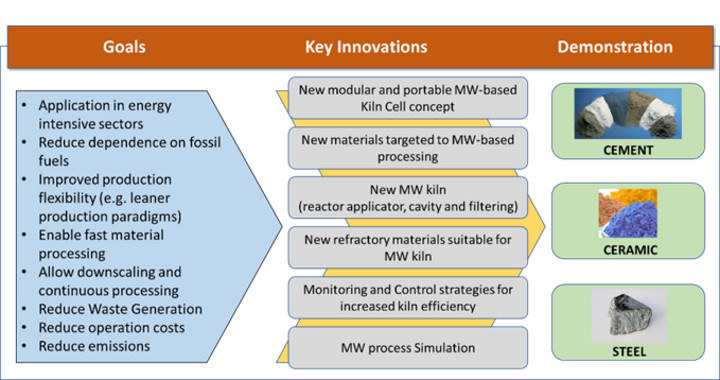

The DESTINY project aimed to realize a functional, green and energy saving, scalable and replicable solution, employing microwave energy for continuous material processing in energy intensive industries. The target was to develop and demonstrate a new concept of firing for granular feedstock to realize material transformation using full microwave heating as alternative energy source and complement to the existing conventional production. The DESTINY system is conceived as cellular kilns in a mobile modular plant, with significant advantages in terms of resource and energy efficiency, flexibility, replicability, scalability and a reduced environmental footprint.

The influence of the DESTINY solutions in terms of stability, process efficiency and characteristics of raw materials, intermediate/sub/final products was investigated to improve performance of the industrial processes within 3 industrial sectors (Cement, Ceramics and Steel). New heating technologies, monitoring systems and numerical simulation tools were used to drive the design and to excel in the outcome.

The industrialization and sustainability of DESTINY high temperature microwave technology was assessed through the evaluation of relevant key performance indicators (KPIs) with life cycle methodologies. With the final aim of ensuring a large exploitation and market penetration for DESTINY, technology-based solution business models, economic viability and replicability analysis were conducted. For guaranteeing industrial transferability, appropriate exploitation and dissemination activities have been defined during and even after the end of the project.

Objectives

The DESTINY project aspired to introduce a “first-of-a-kind” high temperature microwave processing system at industrial level offering a variety of vital benefits to energy intensive sectors: reduced energy consumption, lower lifetime operating costs and enhanced sustainability profile.

The DESTINY system is conceived as cellular kilns in a mobile modular plant designed to cover the “material feedstock-firing-product storage” process in a unique clean system with increased production flexibility. Working with throughputs ranging from 10% to 100% capacity should be enabled without any major loss of the overall process performance.

Objectives focused towards the improvement of efficiency ratios in the following areas:

- Flexibility of ±30% to energy input within RES (Renewable Energy Sources) fluctuations time frames without significant losses in specific energy efficiency

- Improvement in energy efficiency of 40% (depending on different industry and product applications)

- Improvement in terms of resource (fuel) efficiency exceeding the value of 40%

- Decrease in CO2 emissions by 45% (without considering the electricity generation at steady state)

- Decreased OPEX and CAPEX by 15%.

Project timeline:

2018-10-01 to 2022-03-01

Funding scheme:

H2020-NMBP-ST-IND-2018-2020

CE-SPIRE-02-2018,

This project has received European Union’s Horizon 2020 research and innovation funding under grant agreement No. 8270783.

Project consortium:

Keraben Grupo S.A. (Coordinator)

Al-Farben S.A.

Ceinnmat, S.L.

CEMEX Research Group AG

Ciaotech (Gruppo PNO)

Chumillas Technology S.L.

DK Recycling und Roheisen GmbH

ENGIE Laborelec

K1-MET GmbH

National Technical University of Athens - Laboratory of Heterogeneous Mixtures & Combustion Systems

Universidade de Lisboa - Instituto Superior Técnico (IST)

Università Politecnica delle Marche - Department of Industrial Engineering and Mathematical Sciences

Universitat Politècnica de València - ITACA Research Institute (DIMAS)

VDEh-Betriebsforschungsinstitut GmbH

DE

DE EN

EN