Introduction

Decarbonization of the steel industry requires innovative solutions for a maximum possible CO2-lean steelmaking process with the ultimate long-term goal of a net zero-carbon production to be in line with the European Green Deal. To reach a net zero-carbon steelmaking, an adaption of existing integrated routes via Blast Furnace - Basic Oxygen Furnace (BF-BOF) is required. Hydrogen based Direct Reduction (DR) is a promising technology for zero CO2 iron ore reduction. As DR works without any liquid phase, a pre-smelter is demanded as a link between the DR plant and the BOF to convert low-grade Direct Reduced Iron (DRI) into hot metal before being refined. The development of this smelter is in the focus of the current project.

Objectives and Motivation

- Smelter development considering specific issues, such as smelter geometry, suitable refractory lining, slag formation, hot metal carburization, etc.

- Determination of suitable feed materials (DRI based on pellets, sinter, fines, etc.) and carbon carriers

- Implementation of sensitivity analyses for process optimization (e.g., a combination of smelter with direct reduction)

Methodology

- Theoretical consideration of the slag formation process with accompanied thermodynamic modelling (formation of primary and end slag, melting temperature)

- Investigations on the electrical conductivity of the slag

- Basic metallurgical considerations, such as metal carburization, reactions in the burden (calcination, reduction) and in the slag inside the smelter

- Evaluation of the hot metal and its by-products

- Definition of suitable iron carriers for the smelter process (matrix with pros and cons considering DRI and HBI based on pellets, sinter or fines)

- Definition and evaluation of suitable carbon carriers as reducing and carburization agent

- Investigation of steel mill residues (dust materials, sludges and scale) to be directly recycled with the smelter

- Lab-scale smelter tests with varying input materials and additives

- Investigation of a possible refractory concept for the smelter considering issues, such as lifetime, maintenance requirements, resistance against slag, or possible protection through a solidified slag layer

- Definition of a suitable smelter geometry

- Evaluation of critical elements such as zinc or alkalis in case of cycles and enrichment in the process

- Sensitivity analyses of the smelter process considering combinations with a direct reduction plant to define possible operating points with focus on parameters such as Metallization Degree, the carbon content of the DRI, etc.

Results and Application

Basic metallurgical knowledge about the reactions´ smelter bulk as well as knowledge of the slag formation process and the properties of the primary and final slag will be obtained. The carburization behavior of the metal, gas utilization and properties of the hot metal and its by-products will be determined.

Furthermore, suitable iron carriers for the smelter will be determined and knowledge of carbon carriers (alternatives to metallurgical coke), its properties and their effects on the smelting process is generated. The requirements for the chemical and physical properties of steel mill residues for recycling are specified.

The effects of alternative iron and carbon carriers on smelter performance are quantified. Knowledge of expected product qualities (hot metal, slag) and basic information on smelter geometry will be available. A suitable refractory lining concept for the smelter will be created. Possible smelter operating points and derived trends in expected productivity, yield and CO2 emission will be available.

Final hot metal and slag composition with emphasis on carbon, silicon, manganese, sulfur and phosphorus content should be evaluated. The off gas composition will be defined and the suitability of the hot metal and by-products for further processing in different aggregates will be analyzed.

DE

DE EN

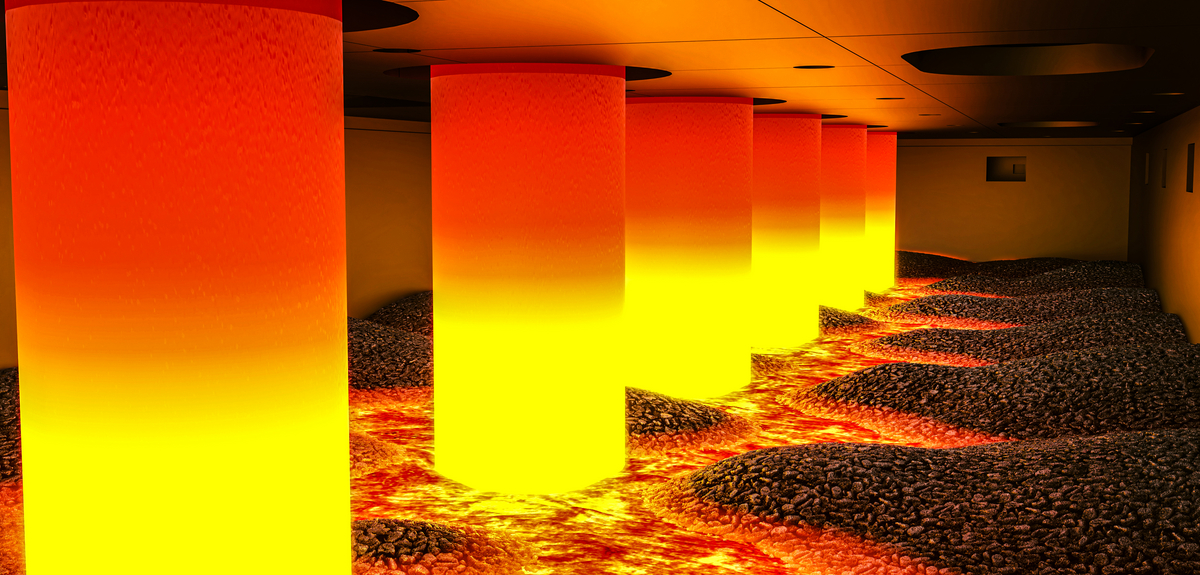

EN![[Translate to English:]](/fileadmin/_processed_/6/4/csm_liquid14_weiss_e50833489d.png)