Project 1.8

Insights into metallurgical processes by means of experimental investigations and thermodynamic studies

Introduction

Slags play an essential role in iron and steel making processes. Different fluxes, such as calcium- and magnesium-containing materials are used to create a basic slag and promote the refining of e.g., hot metal in the Basic Oxygen Furnace (BOF). Exemplarily, MgO-based fluxes are added to reduce refractory wear as a MgO-saturated slag can decrease chemical attack on metallurgical vessels. In addition to BOF slag, the dissolution behavior of additives is also of great importance in EAF slag, secondary metallurgical slags from the ladle furnace (LF) or slags from an electric melting furnace (Smelter), providing important information on process efficiency and product quality.

Polyvalent elements with iron as a prominent example, occur in molten slags in at least two different oxidation states. Among the properties of melts influenced by polyvalent ions are viscosity, surface tension, or the kinetics of nucleation. The status of a polyvalent element, e.g., the ferrous and the ferric iron content in the melt phase, can be quantified by their redox ratio. Electrochemical sensors, such as the voltametric sensor concept, can play a crucial role in evaluating the redox ratio to illustrate the interplay of the thermodynamic, the rheologic, and the electrochemical slag behavior.

One slag parameter being relevant for efficient metallurgical processes is the viscosity. A proper viscosity leads e.g., to fluently flowing tapping processes, an efficient hot metal desulphurization, a good dispersion of non-metallic inclusions, and a moderate refractory corrosion.

Viscosity measurements of primary and secondary steelmaking slags are therefore important and during the project, a modified gas-tight rheometer will be used to measure the viscosity of different primary and secondary metallurgical slags, hot metal, molten scrap, and steel in dependence of the temperature. The project can help to optimise slag systems in production processes but will also support other projects with viscosity data, especially those dealing with fluid dynamic simulations (see Area 3 “Simulation and Analyses”).

Objectives and Motivation

- Generate knowledge about the use of alternative circular slag formers containing calcium, aluminum, iron, magnesium or silicon

- Further insight into the rate determining processes during the dissolution of solid particles (e.g., circular slag forming additives) in slags (e.g., LF, EAF, BOF, electrical Smelter)

- Illustrate the interplay of thermodynamic, rheologic, and electrochemical activity fields focusing on slag coating control in the BOF as well as on foaming mechanisms

- Measurement procedure for a fast acquisition of electrical conductivity data in iron oxide containing melts

- Upgrade of a rheometer with a gas tight chamber to measure viscosities of LF and EAF slag, and slags from H2-plasma reduction (link to Project 2.1 “Continuous HPSR process development” from Area 2 “Decarbonisation and Sector Coupling”)

- Quantify the applicability of the modified rheometer to measure the viscosity of hot metal, molten scrap, and steel in dependence of the temperature

Methodology

- Thermodynamic calculations using FactSage® to calculate melting points of slags and to predict the formation of different phases during the dissolution process

- Screening and selection of Ca-, Al-, Fe-, Mg-, and Si-containing residue materials from refractory recycling (recyclates) and execution of lab-scale dissolution tests with comprehensive sample analyses by means of microscopic and spectroscopic methods

- Assess the dissolution behavior and mechanisms during primary and secondary steelmaking and refining and correlate them with the chemical compositions of the used slag additives

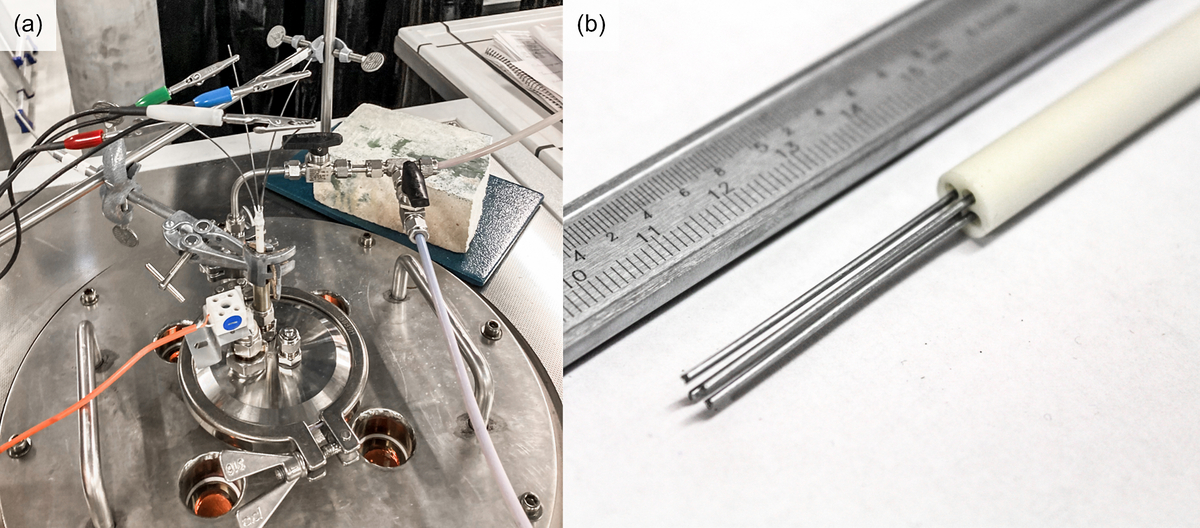

- Potentiostatic cell arrangement for routine measurements of electric conductivity in molten slags considering suitable electrode arrangements, i.e., working electrode, reference electrode for different metal/metal oxide systems

- Measurements in a programmed manner within a frequency band of roughly 1<f<100 kHz to identify a subrange of frequencies, where sample conductivity turns out to be independent of frequency

- Viscosity measurements of slags and metal melts in dependence on the temperature at constant temperature levels below and above liquidus temperatures with comprehensive microstructure analysis and calculate the solid fraction of tested slags in dependence on the temperature using FactSage®

- Determine the break temperature of slags used by a continuous viscosity measurement during continuous cooling at a fixed shear rate

Results and Application

The dissolution behavior of alternative slag formers containing Ca, Al, Mg, Fe, and Si will be described and further insight into the rate determining processes during the dissolution of solid particles (e.g., slag forming additives) in slags (LF, BOF, EAF, Smelter) is expected. Accompanied thermodynamic slag data calculated from FactSage® to describe the slag state and the phase evolution should be made available.

Temperature dependent electrical conductivity data for iron and steelmaking slags and their correlation with viscosity data will be established. Based on a voltametric sensor concept, a fast determination of iron redox ratio in iron and steelmaking slags will be carried out and a temperature dependent evaluation procedure of iron ion diffusion coefficients in molten slags will be established.

Comprehensive temperature dependent viscosity data for iron and steelmaking slags and metal melts are expected. An accompanied determination of the solid fraction in dependence on the temperature using FactSage® should be executed. The influence of crystal size and shape on non-Newtonian behavior should be clarified.

DE

DE EN

EN![[Translate to English:]](/fileadmin/_processed_/4/0/csm_recycle49_weiss_b776401e10.png)