Technology

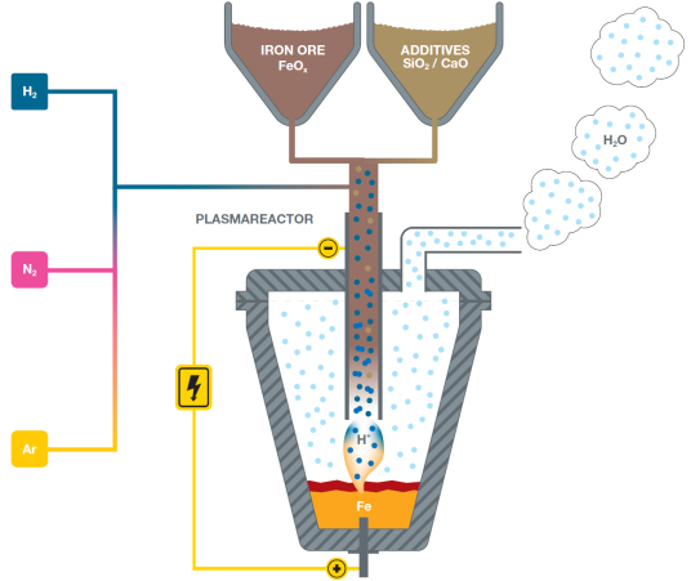

SuSteel (sustainable steel) represented a research and development project for a CO2 free production of crude steel. The technology is based on the usage of hydrogen plasma. Thereby, hydrogen is used as the reduction agent for the iron ore while its plasma state offers the thermal energy for melting the metallurgical iron. The utilisation of hydrogen as the reduction agent inheres the advantage that only gaseous water remains as by-product. Consequently the usual emissions of CO2 can be fully avoided.

The main foci of this research were the generation and perpetuation of the hydrogen plasma, the impact of hydrogen on the refractory lining, and the very details about the process and operational parameters.

Poject abstract

A first lab scale process with a capability of around 100g melt was established and operated at Montanuniversitaet Leoben. The acquired insights were transformed into a reactor scale up (pilot scale) with about 90kg melt capability. This reactor was intended to unveil further process parameters, limitation, and operational aspects during batch mode operations. A subsequent phase was included for further process optimisation.

Project timeline:

01.09.2016 – 29.02.2020

(Followup until June 2023)

Funding scheme:

FFG Project 853393

Project consortium:

K1-MET GmbH

Montanuniversitaet Leoben

voestalpine Stahl GmbH

DE

DE EN

EN