Overall approach

The present project aimed at developing advanced methodologies and tools to support the revamping of gas and steam networks for improving energy efficiency and reducing CO2 emissions as well as energy and management costs. The ongoing pressure toward energy efficiency is expected to push steel companies toward an evolution of gas and steam networks in integrated steelworks through major modifications, such as addition of new junctions, new storage possibilities, additional energy and gas sources. A more dynamic interaction with the energy market is also expected and an increased exploitation of renewable energy resources, which imply fluctuations in the energy costs and increased demand for flexibility of energy carriers distribution and for rapid adaption to changes. Furthermore, the European steel sector is expected to undergo in the medium-long term a gradual transition toward C-lean processes and technologies, characterized by a novel and for many aspects not fully explored coexistence of traditional and innovative processes and production units, such as the Direct Reduced Iron (DRI) /Electric Arc Furnace (EAF) route including Natural Gas (NG) and hydrogen exploitation and/or auxiliary processes exploiting the energy and chemical contents of by-product gases. This gradual transition toward C-lean processes and technologies will indeed affect the gas and steam networks, and will imply a huge revamping of such networks, requiring a re-optimization of the whole network and the re-configuration of aggregates for a full exploitation of the advantages of the performed changes.

Objectives

The system developed within this project faced the above-mentioned challenge and relied on computationally efficient process models exploiting data-driven approaches, such as statistical, Machine Learning (ML)-based and hybrid ones, which allowed forecasting gas and steam productions and demands related to the different aggregates included in the networks and characterizing both standard and more innovative production routes. Moreover, physics-informed algorithms were pplied for modelling the networks topology. The proposed work was, therefore, considered incremental improvement for the relevant aggregate modelling and for the network modelling, as an approach of this extent has so far not been done in previous projects.

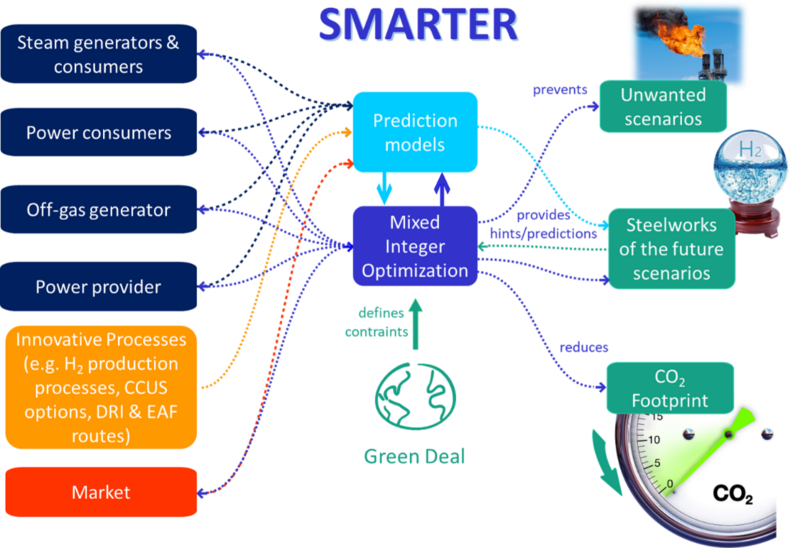

The Figure below shows the approach of SMARTER. Steelworks transform, store, transmit and use various types of energy, where electricity, off- and by-product-gases and steam are among the most important ones. To comply with the goals of the Green Deal, steel producers constantly improve their networks and associated management practices to reduce the waste of resources and increase the overall efficiency. This is a huge revamping task at hand, for which they need the right tools to assist finding the optimum network and aggregate configurations. Such revamping, e.g., new junctions, new storage possibilities, additional sources and innovative processes requires a re-optimization of the whole network and the re-configuration of aggregates, to exploit fully the impacts of these changes.

Regarding the future of steel production, it must be considered that the transition to carbon-lean steel making processes will not take place in one big step. It is assumed that these processes will gradually be integrated into existing plants. Therefore, gas- and steam networks will essentially be affected due to changing process conditions, gas compositions and amounts, etc. This must be considered for an overall evaluation of the benefits and effects of implementing innovative process units. Technically, there were three mayor elements that must be considered within the solution:

- Models for all relevant units / equipment parts are required to forecast the demand and production of consumers and producers

- Models for the networks, their switch/junction configurations, and pipelines

- A rigorous optimization/controller that takes all these models and calculates a solution for the flow configuration

Moreover, the computation of the optimal solution should be fast enough to allow its implementation, therefore suitable approaches should be investigated to speed up the optimization procedure mainly by investigating into two (possibly complementary and not mutually exclusive directions):

- Reaching a trade-off between precision, accuracy, and time consumption

- Distributing the computing

Framework

Project timeline:

2021-07-01 to 2024-12-31 (48 months)

Funding scheme:

The project SMARTER received funding from the Research Fund for Coal and Steel (Grant Agreement no. 101034060).

Project consortium:

- Scuola Superiore Sant’Anna (Italy, Coordination)

- ArcelorMittal Bremen GmbH (Germany)

- INGAVER Innovative Gasverwertungs-GmbH (Germany)

- K1-MET GmbH

- VDEh Betriebsforschungsinstitut GmbH (Germany)

- voestalpine Stahl GmbH

DE

DE EN

EN