Overall approach

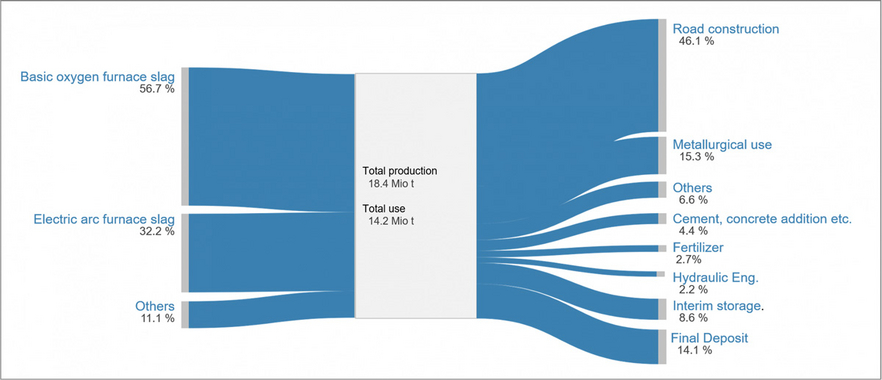

Ferrous slags are mineral co-products in the iron and steel industry. In addition to their process related tasks, slags have great potential in terms of resource conservation. Steelmaking slags are usually utilized as an aggregate for road constructions or recycled within the metallurgical process. Further applications can be found in the cement, concrete and fertilizer industry or in hydraulic engineering (Figure 1).

Latest discussions concerning the valorisation of steelmaking slags and forthcoming changes in the legal framework conditions (national and international level) may lead to a decline in the currently high level of utilization in the traditional field of application as constructional material.

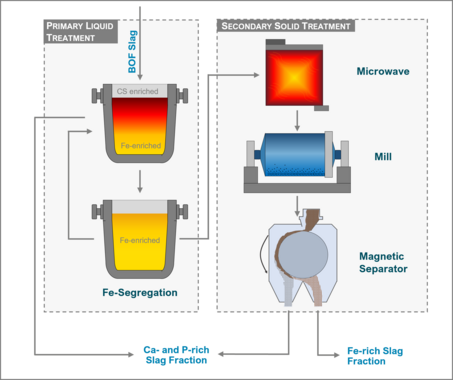

The RFCS project Slagreus dealt with an optimization and extension of the internal recycling rate of Basic Oxygen Furnace (BOF) slag. Furthermore, external valorisation were evaluated and improved. In the scope of the project, a new treatment process was developed resulting in an Fe-enriched product, which can be reused within the steel production process and a mineral fraction, which is expected to be utilized as an additive in the cement and fertilizer industry. As a result, the material efficiency of the iron and steel industry can be increased, whilst preserving natural raw materials and avoiding additional landfill volume.

Objectives

The project focused on the development of an innovative process chain resulting in a Fe-enriched product and a reactive calcium silicate rich fraction. The treatment process consisted of a liquid Fe-enrichment by slag circulation, a microwave treatment of the solidified enriched Fe-fraction, grinding and a magnetic separation (Figure 2). While the Fe-enriched fraction was tested as secondary raw material in the metallurgical process (substitute for iron ore fines), the Ca- and P-enriched fraction were evaluated as a cement additive and a lime fertilizer.

Furthermore, an off-line prediction tool aiming to estimate the expected quality and quantity of slag fractions as well as the overall yield of the processes was developed. Based on the gained knowledge and the prediction tool, technical-, economical- and environmental assessment of the applied concept were performed.

The main objectives of Slagreus were:

- Development of an innovative process chain

- Optimization of the separation and recycling of valuable metals (internal recycling)

- Improved utilization of the mineral fraction and evaluation of its suitability as an additive in the cement or fertilizer industry

- Development of an off-line prediction tool

DE

DE EN

EN