Overall approach

In the context of the transition to low-carbon, green and sustainable steel production in Europe, disruptive technologies to reduce the environmental footprint as close to zero as possible, seamless digitalisation of production processes, and skilled people to co-design and understand the transformation process are necessary. The consortium of DiGreeS will address these needs by implementing an integrated digitalisation approach across the steel value chain, enabling better use of process data collected and ensuring the involvement of human experience for easier industrial integration.

The aim of DiGreeS is to develop a user-friendly digital platform for networked production based on novel and soft sensors and related approaches and models to support efficient feedstock verification, real-time control of electric arc furnace crude steel production and increasing process yield while improving the quality of semifinished and finished sheet metal blanks. In this context, the potential of artificial intelligence techniques will be fully exploited to support the optimal use of industrial data, and different scenarios specific to each use case will be modelled. DiGreeS has the potential to save up to € 800 million in costs annually and reduce CO2 emissions from the steelmaking industry by up to 6 million tonnes per year.

Objectives

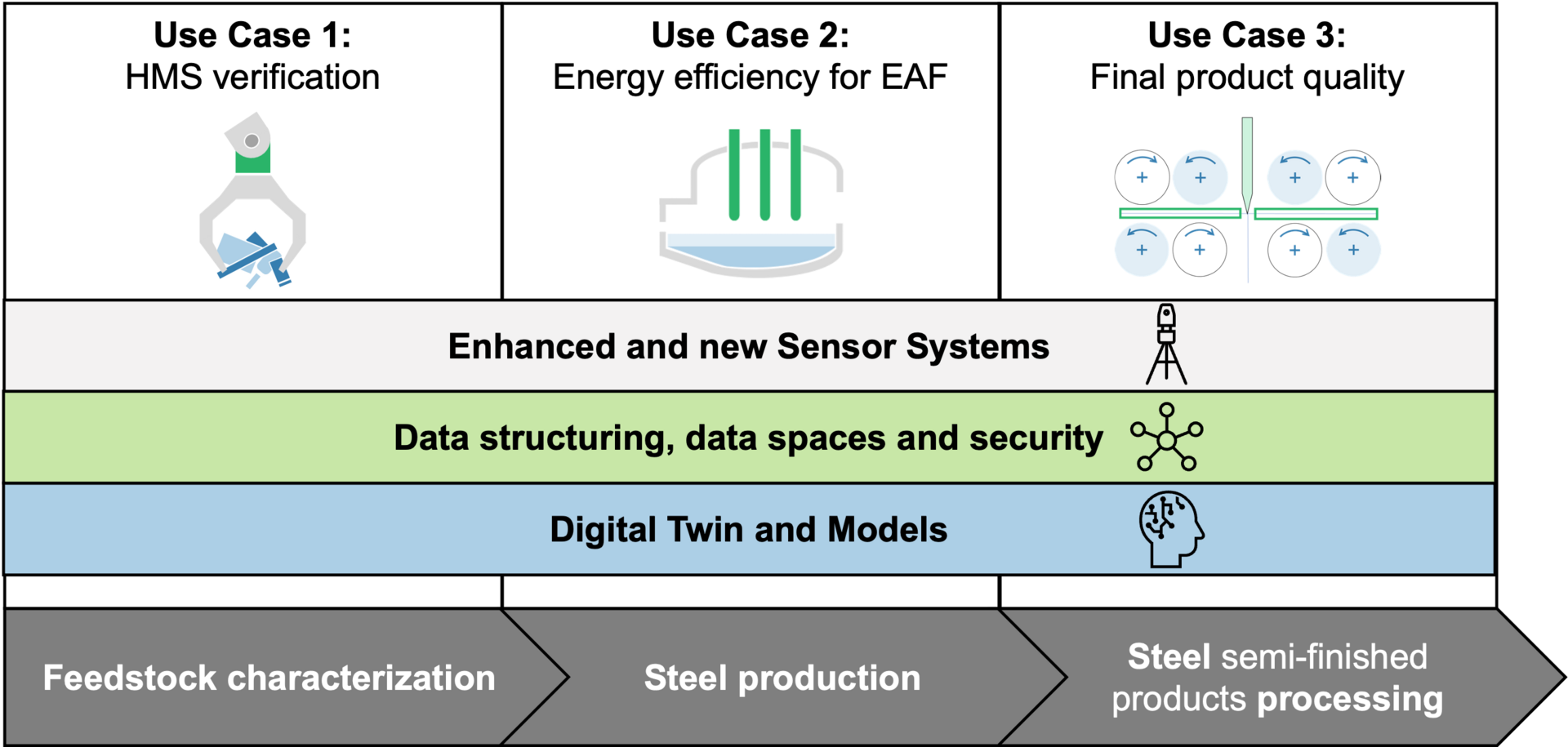

The digital platform will be implemented and verified in industrial process lines of the three use cases:

- Scrap/secondary raw material verification on the example of heavy melting scrap (HMS)

- Optimisation of the electric arc furnace processes using novel sensors and soft sensors with digital process twins

- Optimisation of the levelling of steel sheets and avoiding rework in the production of sheet metal blanks

- Establishing a platform for digital twins that covers the entire steel production value chain

- DiGreeS aims to improve the quality of crude steel and finished products, optimize scrap usage, and improve energy efficiency in the steel production process.

PROJECT TIMELINE:

1 November 2024 – 30 April 2028 (42 months)

FUNDING SCHEME:

This project is funded within HORIZON-CL4-2024-TWIN-TRANSITION-01-44 – Digital transformation and ensuring a better use of industrial data, which can optimise steel supply chains (Clean Steel Partnership) (IA).

PROJECT CONSORTIUM:

Starting with the project coordinator, the consortium is composed as follows:

- Fraunhofer IZFP

- K1-MET GmbH

- Számítástechnikai és Automatizálási Kutatóintézet (SZTAKI)

- Fraunhofer Austria

- VDEH-Betriebsforschungsinstitut GmbH (BFI)

- Saarstahl AG

- Tata Steel Nederland Technology BV (TSNT)

- Voestalpine Steel and Service Center GmbH

- Spectral Industries

- ESTEP

DE

DE EN

EN