Introduction

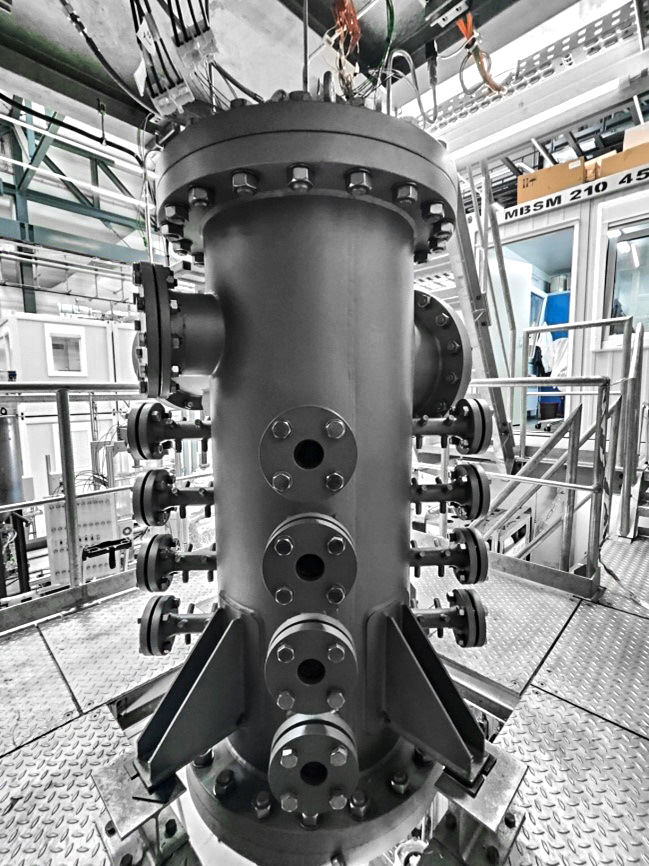

Alternative reducing agents (ARAs) for the blast furnace (BF) process, such as pulverized coal (PC), are state-of-the-art being injected into the BF tuyere zone to partially replace metallurgical coke. PC grades show different conversion behavior depending on their chemical composition. For a deeper understanding of the chemo-kinetics during coal conversion and for a detailed analysis of other solid fuels, such as secondary carbon carriers (e.g., torrefied biomass) a highly sophisticated test reactor (called ARA reactor) will be operated.

The transformation of steel production from the BF to the direct reduction (DR) route requires an improved and fast analytics of the produce Hot Briquetted Iron (HBI) coming from the DR shaft. The knowledge e.g., about the iron valence in the HBI allows an indication of the DR process efficiency and stability.

At the end of the iron and steelmaking process chain, on-line, or at least at-line (by-pass) analysis applications for dusts, slags, and scrap must operate in a fast way to execute processes changes more efficiently according to the residue composition. Exemplarily, the slag analysis from the ladle furnace (LF), is used to define a change of additives for the LF treatment. Analysis of scrap as an important secondary raw material possibly directly at the scrap yard (scrap supplier site or in the steel plant) represents an effective measure to obtain information about the scrap quality before planning the further scrap logistics (sorting and charging).

Objectives and Motivation

- Quantify the reactivity of alternative reducing agents under BF similar conditions

- Develop and improve analytics for raw materials (pulverized coal, PC, Hot Briquetted Iron, HBI) and by-products (BF dust and slags)

- Define the carbon origin in the BF dust (metallurgical coke or PC) using Raman spectroscopy and quantify the possibility of an on-line application

- Develop and improve analytics for metallurgical slags (Basic Oxygen Furnace (BOF) and ladle furnace (LF) slag) and quantify the possibility of on-line applications

- Improve a calibration-free LIBS evaluation algorithm for LF slags and extend it to other metallurgical slags

- Develop a portable spark discharge-supported Laser Induced Breakdown Spectroscopy (LIBS) sensor for slag and scrap characterization

Methodology

- High-temperature reactivity measurements (conversion tests) of PC blends and other alternative reducing agents, such as pyrolyzed biomass using a pressurized injection reactor with varying testing parameters (e.g., pressure, temperature, gas composition)

- Spectroscopic analyses of HBI using LIBS and Raman with accompanied microscopic imaging using Scanning Electron Microscopy (SEM) and a computer-assisted phase detection routine

- Spectroscopic analyses of BF dust and slags (BOF, LF) using LIBS and Raman and determination of the iron valence and extended parameters (e.g., free lime) in metallurgical slags

- Development of a portable LIBS system for slag and scrap analyses

Results and Application

Regarding the use of alternative reducing agents, the sources tested should be evaluated in terms of their suitability for the BF process. Accompanied deeper understanding of chemo-kinetic BF process related phenomena during pulverized conversion is expected. Coming from the BF top gas, the possibility to quantify the origin of the carbon in the BF dust will be evaluated by using a LIBS-Raman coupled method.

For HBI as another raw material being investigated in this project, a method for a faster chemical analysis should be developed using spectroscopic and microscopic methods with an accompanied computer-assisted image processing tool.

Further downstream the process chain, a calibration-free and fast responding analysis system based on LIBS should be developed being applied to primary and secondary metallurgical slags as well as to scrap representing one important secondary ferrous raw material for a sustainable steelmaking.

DE

DE EN

EN